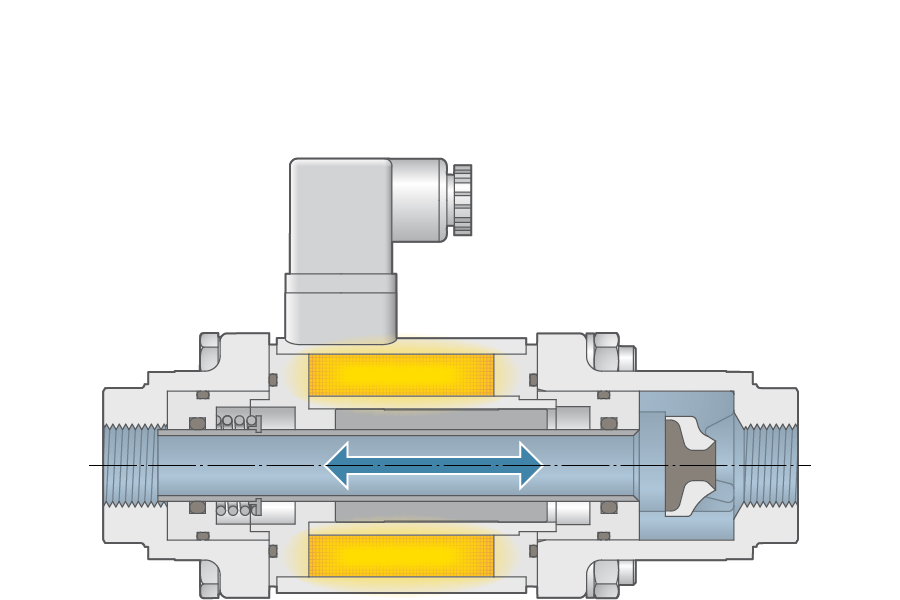

Valves with coaxial design are pressure balanced. Switching capacity remains constant and the valves switch safely – regardless of vacuum, low or high pressure service. The media pressure has no effect on the switching behavior except at the highest pressure level due to seal friction.

Back pressures up to the full pressure rating are possible for valves with an actuated pneumatic or hydraulic drive - even without seat leakage. When closure depends on the valve’s spring, the output pressure can be up to 240 psi higher than the inlet pressure (240 psi counter pressure). The seal tightness at the valve seat is ensured up to this value.

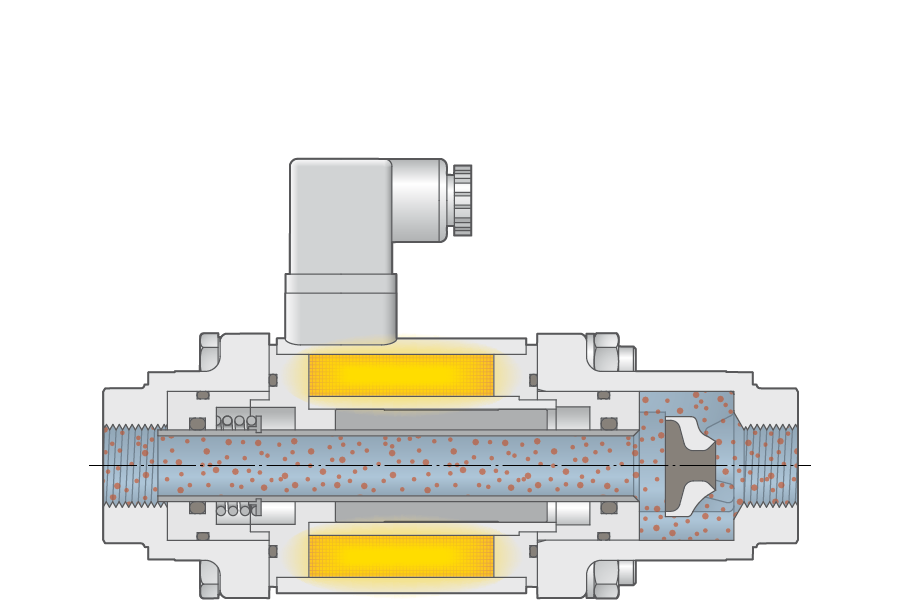

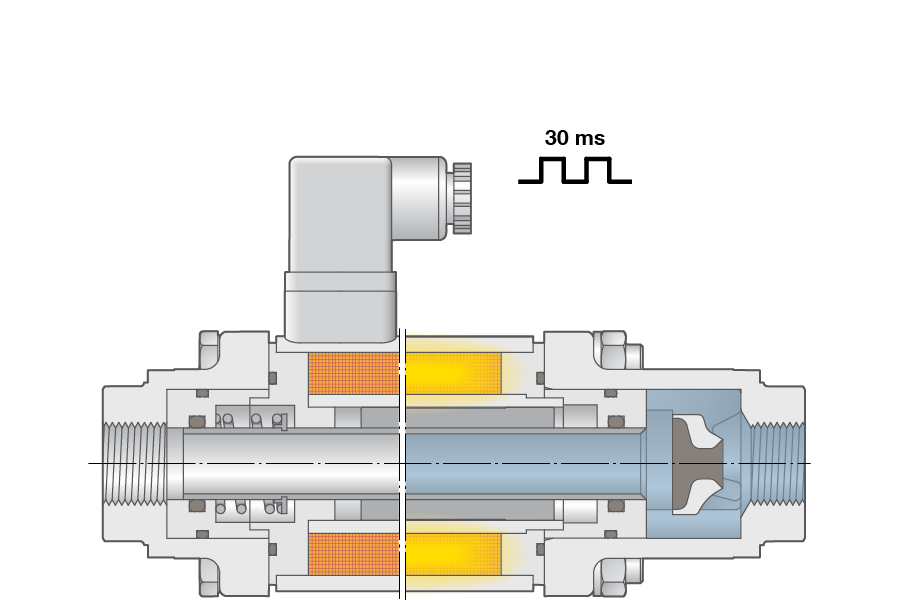

The unique valve design of the co-ax® valve minimizes wear on the valve seat even when used with heavily contaminated media. Due to the special design, co-ax® valves are maintenance-free. The construction of the co-ax® valve allows media flow in both directions - the flow direction can alternate without affecting performance. The pressure-balanced and extremely compact design allows for the fastest opening and closing speeds. co-ax® valves achieve reproducible switching speeds as low as 25 ms.

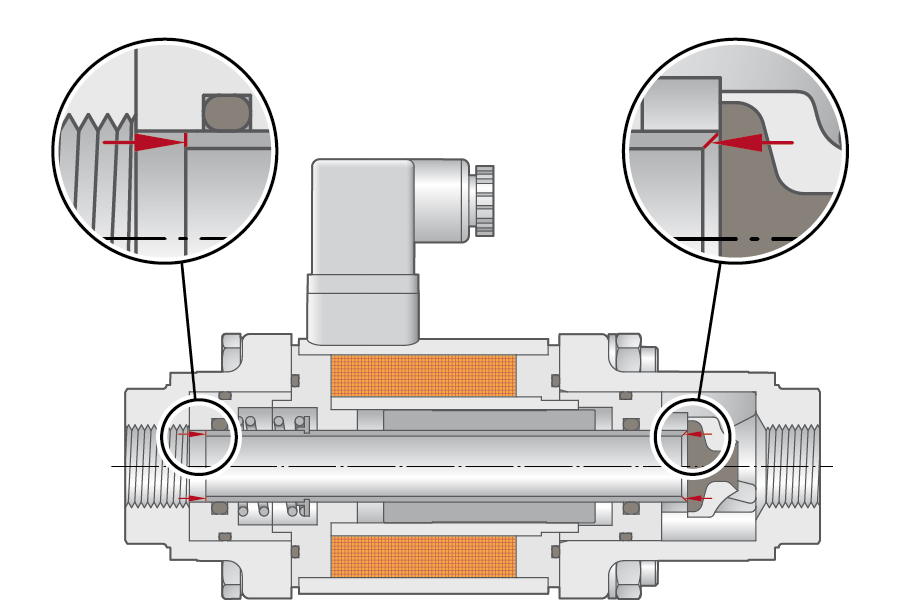

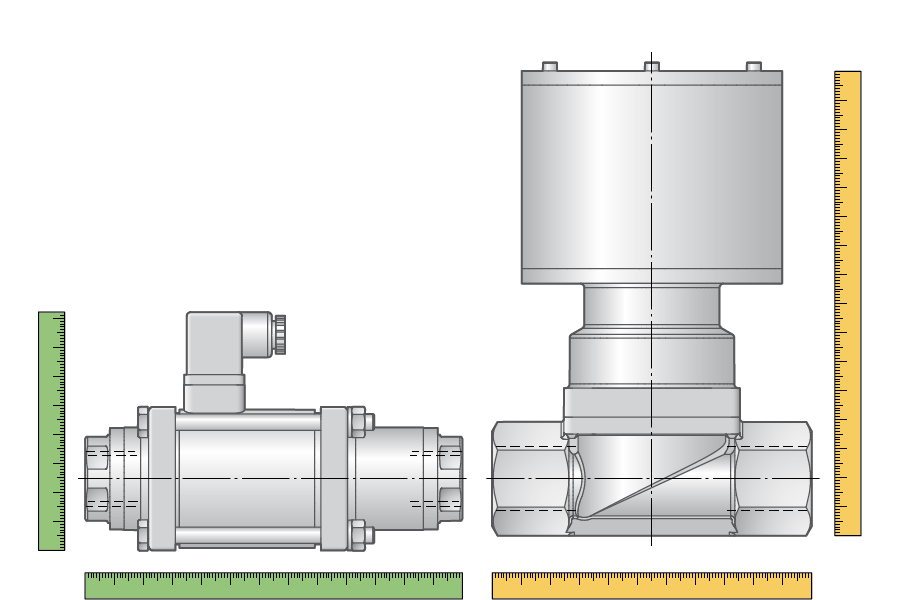

The valve seat, the control tube and the actuator are aligned in a common reference axis. This extremely compact coaxial design provides advantages in systems where valves have to be installed in a single, modular or manifold arrangement under very tight installation conditions.

Coaxial valves are particularly suitable for mechanical and plant engineering lubricant requirements. Other possible uses include vacuum and gas technology, test bench construction, ship and rail engines, and filling and dosing technology. The design of the valves is media and application specific. By selection of suitable seals, gaseous and liquid media, as well as dirty or gelatinous media (oils, emulsions, coolants and lubricants) can be handled.

Our website’s homepage shows many valve versions that are suitable for a large variety of applications and media. Contact us for selection assistance from numerous variants and also special designs that are not listed on our website. From our product line, we are confident that we can offer a suitable valve for your requirement.

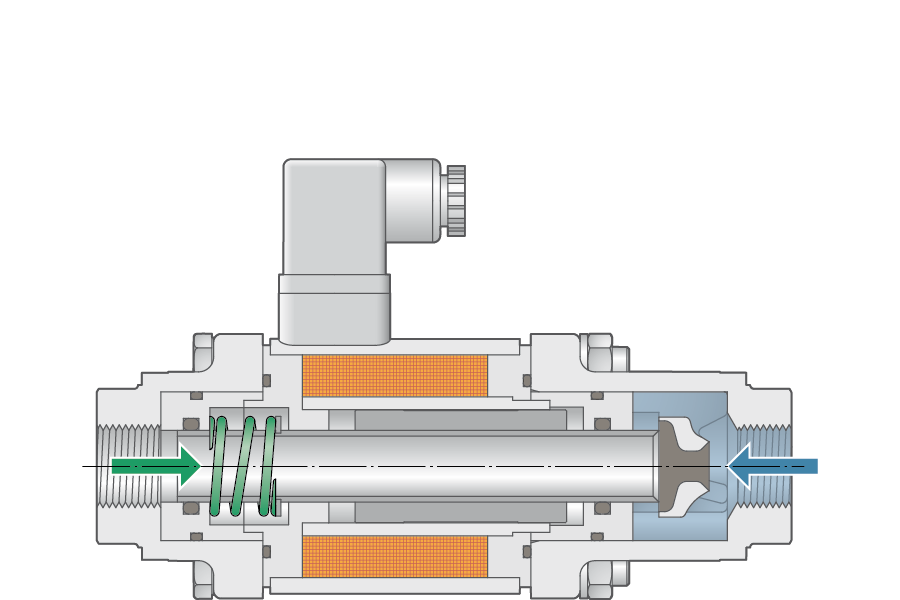

The coaxial design keeps forces within the valve balanced regardless of system pressure and Δp. Performance remains precise and dependable for vacuum through high pressure applications. Unlike conventional valves, coaxial valves require no minimum pressure differential in order to function.

When the valve is closed, the pressure at the outlet side can be higher without any leakage.

The unique coaxial valve design minimizes wear of the valve seat even where extremely contaminated media is involved. Due to the special design with only a single moving part - no stem seal or external actuator / operator - coaxial valves do not require maintenance. Even under extreme conditions, coaxial valves have up to ten times longer service life than conventional valves.

Pressure balanced design provides fast, repeatable operation in less than 30 milliseconds. Thus, the coaxial valve is one of the fastest valves that can be specified.

The valve design allows media to flow through in both directions, thus eliminating the need for multiple valves.

The coaxial valve design provides a compact package by eliminating bulky actuators.