To achieve greenhouse gas neutrality, hydrogen is an important alternative to fossil fuels. In addition to industry applications, green hydrogen plays a major role in the decarbonization of the energy sector and mobility. co-ax® valve technology has proven itself in the entire hydrogen value chain - from hydrogen production to consumption. When developing new technologies, we work very closely with our customers to face current and future challenges.

This process, referred to as hydrogen embrittlement, can be prevented by using suitable materials such as austenitic steels (316 or 316L).

In order to ensure safety, especially in enclosed spaces, the tightness of installed components is of key significance.

The initial pressure of the hydrogen is constantly being increased, the reason why pressures of various intensities have to be controlled.

|

PCD-H 10 |

Pressure Range Orifice Connection CV Value Material |

|

Possible Applications |

|

KBS 15 |

Pressure Range Orifice Connection CV Value Material |

|

Possible Applications |

|

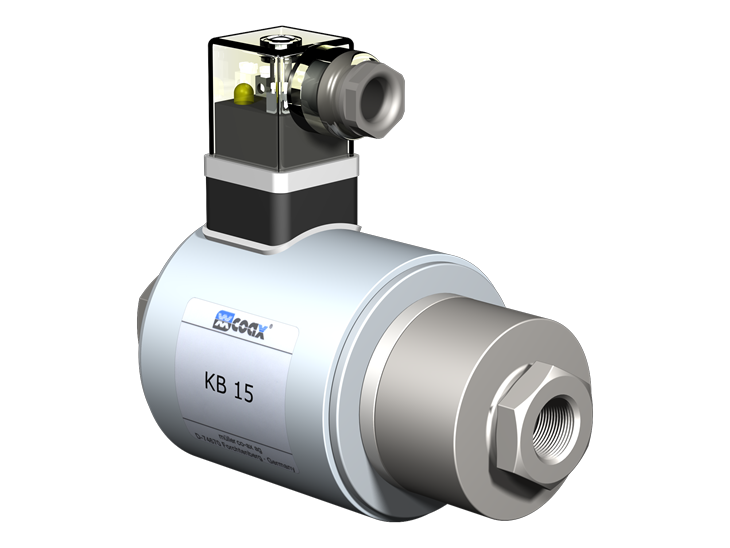

KB 15 |

Pressure Range Orifice Connection CV Value Material |

|

Possible Applications |

|

MK |

Pressure Range Orifice Connection CV Value Material |

|

Possible Applications |

|

VMK |

Pressure Range Orifice Connection CV Value Material |

|

Possible Applications |